Air springs are being used as Secondary suspension in Rail coaches. The primary suspension in Rail coaches is helical coil spring. The efficiency of metallic helical coil springs is less than 80%. To have additional suspension effect in rail coaches, secondary air springs are installed. There are four air springs fitted in each rail coach. Since air is compressible and absorbs abnormal disturbances due to vibrations, jolts, poor tracking, undulation on rail. SI Air Springs in rail coaches provide a smooth ride with comfort. Also, these air springs supports for a noise free movement of trains.

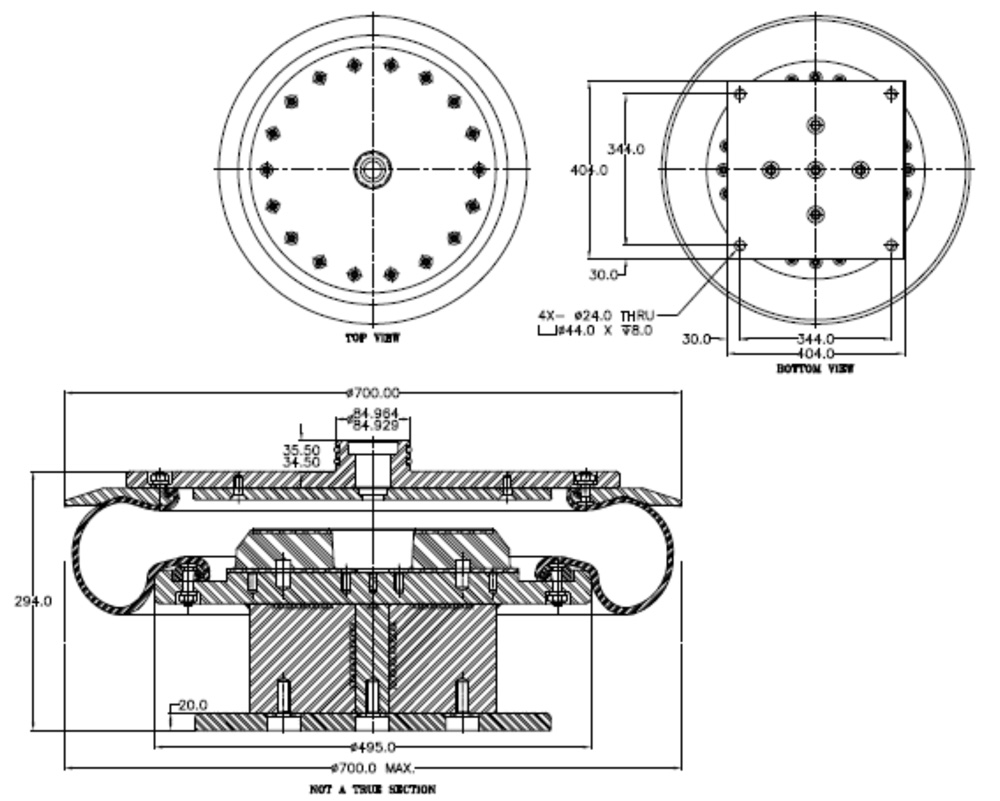

Rail Assembly 120kN capacity

| Operating range | 294mm |

| Loading capacity at 6bar pressure, 294mm height | 130kN |

| Maximum diameter | 700mm |

| Operating temperature | -40° – +77°C |

| Material | Polychloroprene Rubber |

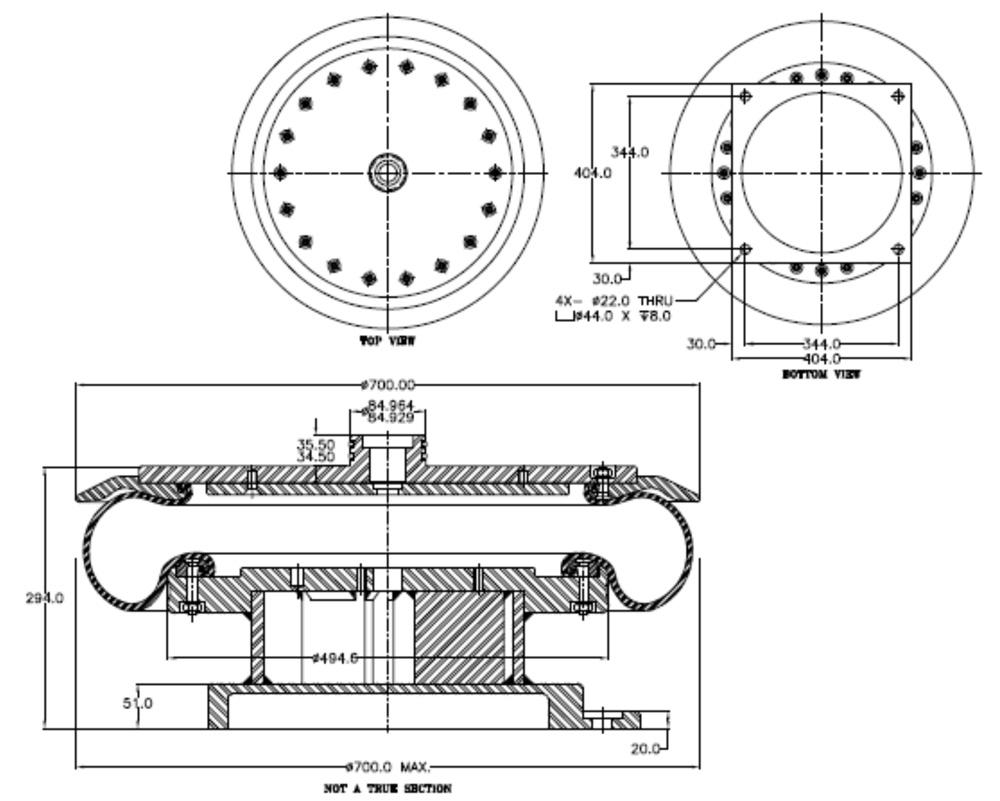

Rail Assembly 140kN capacity

| Operating range | 294mm |

| Loading capacity at 6bar pressure, 294mm height | 155kN |

| Maximum diameter | 700mm |

| Operating temperature | -40° – +77°C |

| Material | Polychloroprene Rubber |

Rail Assembly 160kN capacity

| Operating range | 294mm |

| Loading capacity at 6bar pressure, 294mm height | 155kN |

| Maximum diameter | 700mm |

| Operating temperature | -40° – +77°C |

| Material | Polychloroprene Rubber |

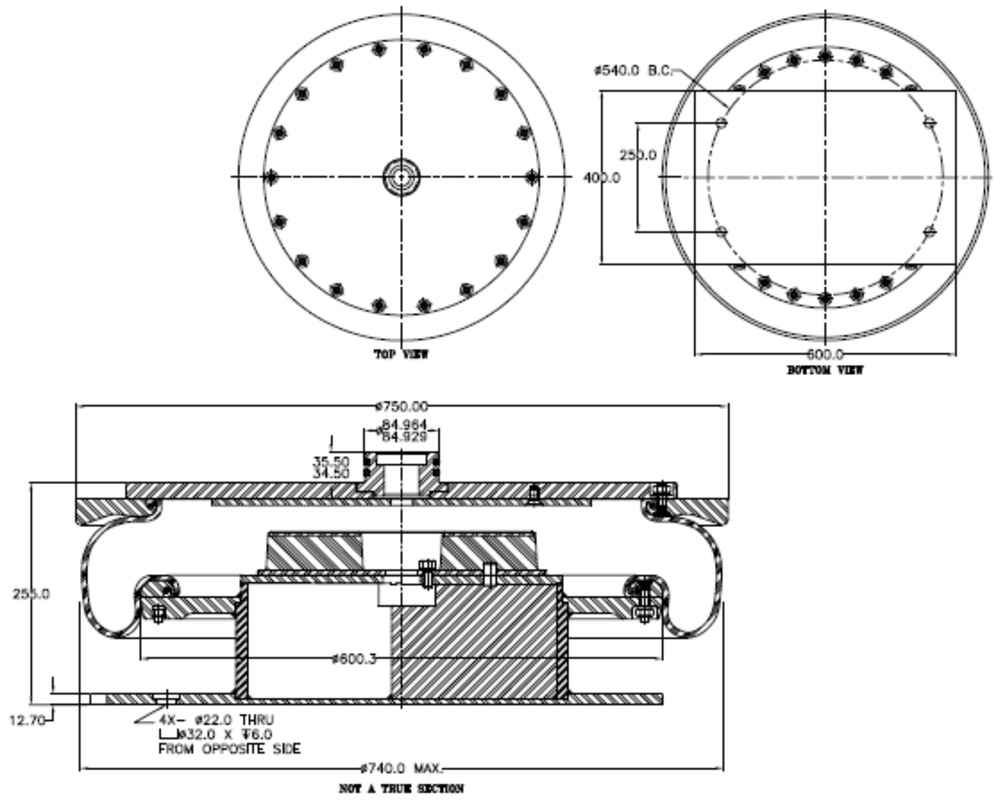

Rail Assembly 180kN capacity

| Operating range | 294mm |

| Loading capacity at 6bar pressure, 294mm height | 190kN |

| Maximum diameter | 740mm |

| Operating temperature | -40° – +77°C |

| Material | Polychloroprene Rubber |