SIAS has earned goodwill as being the long standing supplier to all leading Indian Automotive manufacturers.

There are three type of air springs – Rolling sleeves, Rolling lobes, and convolute assembly. Rolling sleeves and rolling lobes are used to absorb more vibrations and produce more comfort, while the convolute type are used to carry higher load and more lateral movement. Suspension efficiency is determined from natural frequency, which is related to static deflection.

Rolling Sleeves

Rolling sleeves are used in bus suspension for better ride comfort. The suspension must be soft to obtain a good level of ride comfort, and at the same time be firm to maintain good tire to ground contact in order to ensure safety. The ability of re-levelling gives the possibility for air suspensions to be designed softer than conventional suspension in order to provide better ride comfort. Rolling sleeves have the greatest lateral spring rate, apart from a long stroke. The change of cross sectional area of the air springs when axially defected is lesser, so it is easy to achieve low frequencies.

Rolling Lobe Air Springs

Rolling lobe air springs are used in bus and truck suspension where comfort and load carrying capacity are required. These air springs have high stroke length and to some extent angular movement.

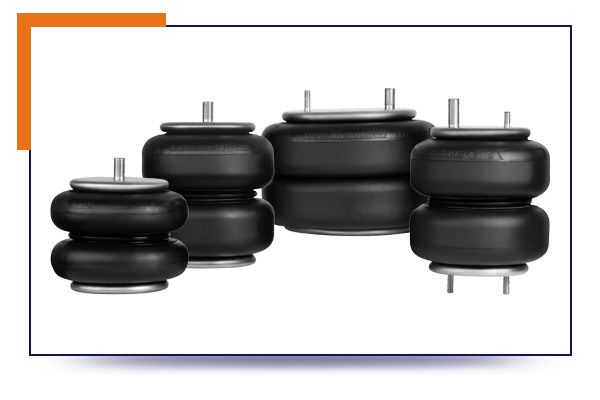

Convolute Air Springs

Convolute air springs are used in trucks for heavy duty suspension. Convolute air springs have short stroke length. Two convolute or three convolute air springs are used according to the required stroke length. The thrust of the air bellows depends on the height of the bellow. When height increases the thrust decreases because of the change in the effective area. Other advantages of convolute air spring are angular movement and mis-alignment between top and bottom convolutes. They can be operated with the lowest compressed height.

Bellow Construction

Natural Rubber based compound is used as inner liner and outer cover. This compound has the advantage of very good tensile properties, dynamic properties, tear strength, elasticity, and abrasion resistance.

Polycholorprene based compound used as inner liner and outer cover for high temperature resistance and environmental resistance application. This compound has the advantage of very good tensile properties, dynamic properties, tear strength, elasticity, and abrasion resistance.

High strength fabric used to get higher stiffness of bellow and increased burst pressure.